Risk assessment

Before operating any machine, it is crucial to conduct a risk assessment to identify potential hazards. This includes examining the work environment, the condition of the roll cutter machine, and the specific tasks to be performed. The assessment should be thorough and consider all aspects of the cutting process.

Training and education

Operators must receive continuous and appropriate training on the safe use of roll slitter machines. This includes instructions on machine handling, emergency procedures, and the use of personal protective equipment (PPE). Training should be both theoretical and practical, ensuring that workers fully understand the risks and safety measures.

Personal protective equipment (PPE)

The use of PPE is essential to prevent injuries. Common PPE items include cut-resistant gloves, safety glasses, hearing protection, and appropriate clothing that does not get caught in the machine. It is the employer’s responsibility to provide and maintain this equipment.

Preventive maintenance

Regular and proper maintenance of roll cutting machines is crucial for their safe operation. This includes periodic inspections of critical components, lubrication of moving parts, and replacement of worn-out parts. A well-planned preventive maintenance program can prevent mechanical failures and reduce the risk of accidents.

Standard operating procedures

Establishing and following standard operating procedures (SOPs) helps ensure that slitting machines are used safely and consistently. SOPs should include clear instructions on machine operation, setting cutting parameters, loading and unloading rolls, and emergency steps.

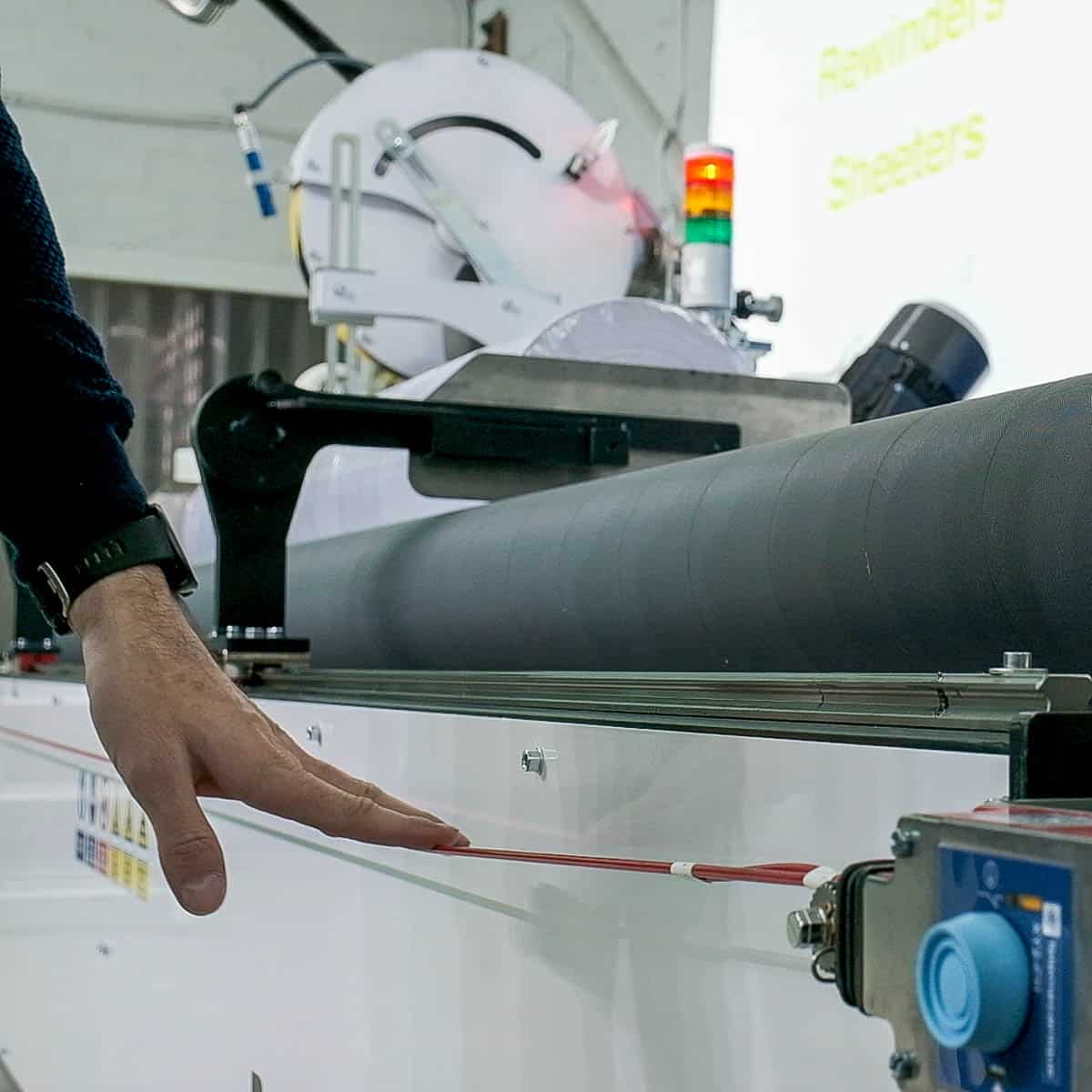

Use of safety technology

Incorporating advanced safety technologies in machines can significantly reduce the risk of accidents. This includes emergency stop systems, safety sensors that detect the presence of people near the machine, and locking devices that prevent the machine from operating during maintenance tasks.

Safety culture

Promoting a safety culture in the workplace is fundamental. This involves encouraging open communication about risks, motivating workers to report unsafe conditions, and recognizing safe practices. A strong safety culture is built through the commitment and participation of all organizational levels.

Conclusion

Ensuring safety when using roll cutting machines not only protects workers but also improves the efficiency and productivity of the work environment. Implementing risk assessments, providing appropriate training, using PPE, performing preventive maintenance, following SOPs, incorporating safety technology, and fostering a safety culture are essential measures to achieve a safe and efficient work environment.