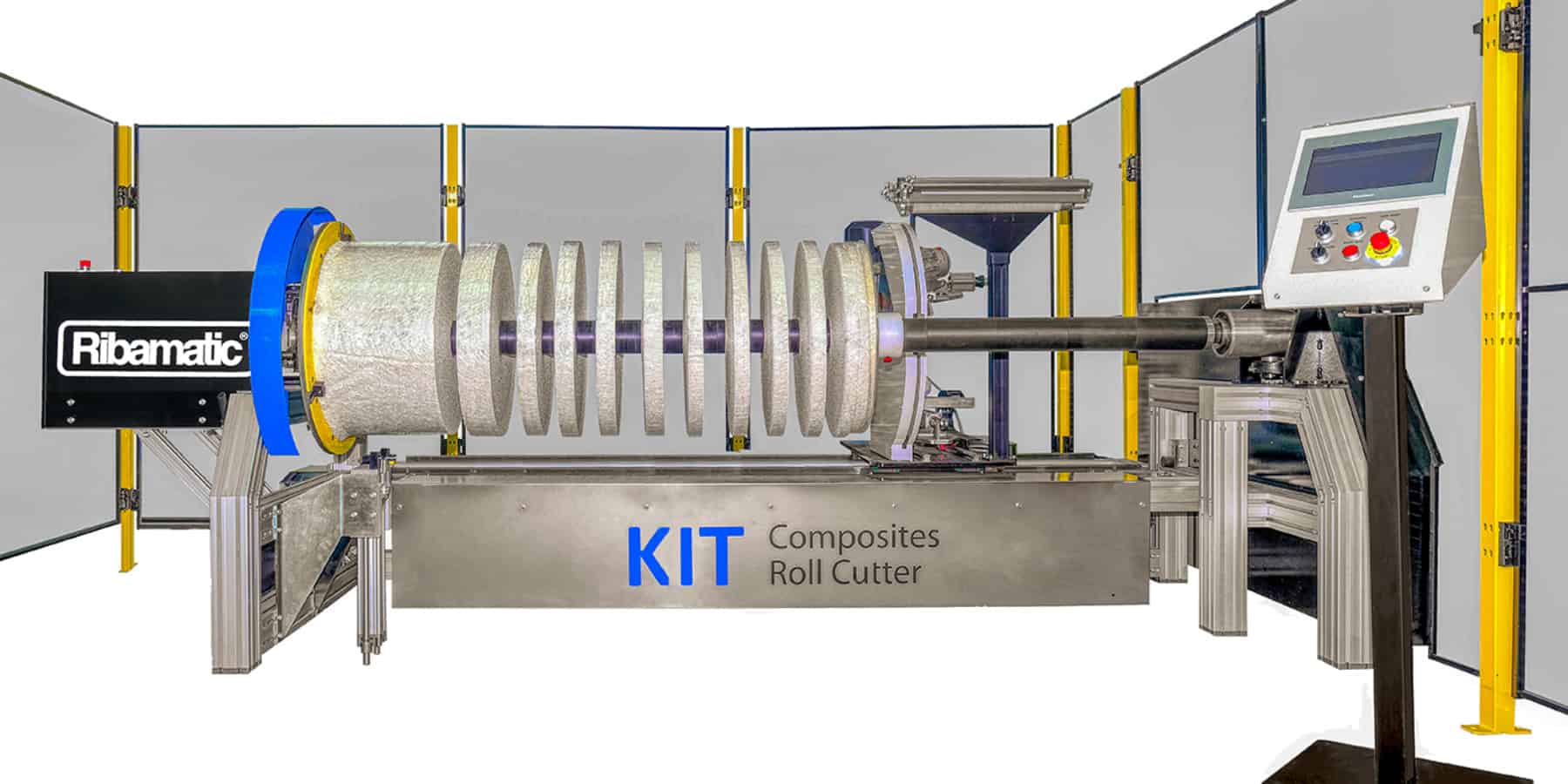

Roll slitter KIT Main features

- Automatic machine operated via HMI touch screen.

- Connectivity to MIS/ERP to send cut orders to the machine.

- Wi-Fi remote online connection.

- Laser system to automatically find the edge of the roll.

- Equipped with central shaft for soft rolls.

- No need to put the roll in any specific place onto the rollers, just drop it at any place.

- Automatic self-sharpening, no need to change the blade.

- Cutting head locks and unlocks automatically, we avoid screwing every time.

- High precision measurements – 0.01 mm.

- Any core size can be cut, no need to rewind the roll before using the machine.

- Automatic cooling system – air gun 0º.

KIT is a fully automatic and programmable roll cutting machine.

Efficient, time-saving, with minimal use from personnel and equipment.

However, it is a heavy-duty roll slitter machine to cut different kinds of materials specially indicated for textiles, woven and knitted fabric, but also fiberglass, nonwovens and carpets. Many industries, such as fiberglass, filtering, health, geotextiles or apparel, are cutting with KIT.

KIT is a fully automatic and programmable roll cutter machine, a standalone machine with high loading capacity and high production speed.

The fully automatic KIT roll cutting machine is designed for high demand on performance and cutting quality, so the machine is specially suitable for large quantities. Complete cutting programs can be created and saved on the operation panel. The number of cuts, the respective strip width and the resting time of the circular knife on the shaft for safe separation of the cardboard tube can be defined in the program.

The advanced technology used in this roll slitting machine allows the purchaser to be competitive and offer high-quality roll deliveries. KIT is the best roll cutter for the leather industry, medical and health sector, face covers or protecting masks manufacturers, as well dressing or protective gowns makers.