Roll slitter TOP30PRO Main features

- With this roll slitter you can cut any kind of material in roll form with exactness.

- The shaftless design allows for easy roll handling onto the rollers.

- There’s no need to position the roll in a specific place on the rollers; you can simply drop it anywhere.

- The cutting head locks and unlocks automatically before the cut, eliminating the need for manual screwing each time.

- The blade sharpens itself automatically, so there’s no need to change it.

- You can make a cut in just 10 seconds.

- Each cut is neat and clean, leaving no wires behind and no melted surfaces.

- Achieve high-precision measurements with an accuracy of 0.01 mm.

- You can cut rolls of any core size without needing to rewind them before using the machine.

- The automatic cooling system operates efficiently with an air gun at 0º.

- The patented blade inclination system ensures precise and reliable performance.

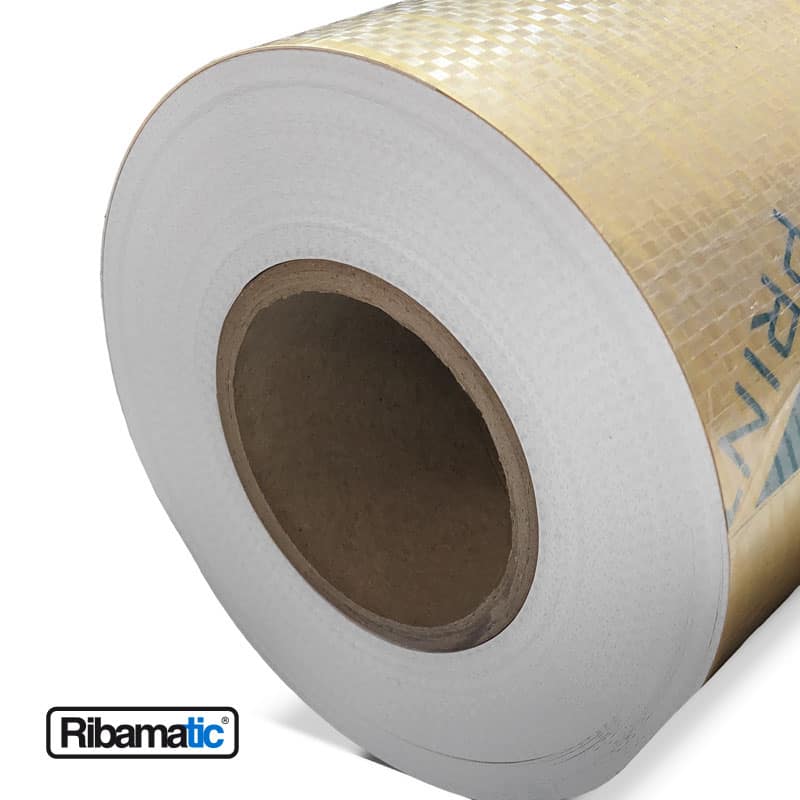

The TOP30PRO roll cutter reliably and accurately slits nonwovens, fiberglass, polyester fabrics, and canvas. It is specifically designed for the printing industry and suppliers of dye sublimation fabric, including 100% polyester, printable apparel fabrics, contemporary apparel, light boxes, and banners.

Our roll slitting machine cuts damaged inner cores effortlessly, without requiring fabrics to be rerolled beforehand. It can handle cardboard cores of any size. With heavy rolls designed to be loaded onto the cradle, the machine prevents issues caused by damaged cores.

The TOP30PRO efficiently processes any kind of roll material. Its blade cuts through both the material and the core in just a few seconds. Workers can easily place the roll onto the rollers, ensuring a safe and straightforward operation.

Our roll slitting machine is specifically designed for cutting digital media rolls, including PVC banners, polyester fabrics, and vinyl, as well as raw materials like fiberglass, carbon fiber, carpets, felts, and textiles. The rubber industry is one of our primary sectors, with EPDM rolls being slit into various widths. Bitumen and asphaltic roll manufacturers also use this machine to prepare rolls for their suppliers.

The fully automatic blade sharpener sharpens both sides of the blade, ensuring it is always ready to cut. If the blade dulls from usage, there is no need to replace it—simply press the sharpener button on the control panel for 10 seconds, and the blade will be ready to work again.

An adjustable blade lubrication system is installed to keep the blade cool during cutting. This 0ºC system prevents the blade from heating up during the cutting process.

A digital counter displays cutting width sizes and includes an option to set a 0 point. The machine automatically stops when it reaches the programmed size.