This machinery plays a fundamental role in industries that handle materials such as paper, plastic film, foil, and other flexible materials, ensuring the process runs smoothly from start to finish.

Using a roll slitter not only improves production efficiency but also helps reduce waste and optimize material use. Without this tool, industries would struggle to handle large volumes of materials effectively. Commonly employed in sectors such as packaging, printing, and label production, the precision and consistency provided by roll slitters are essential for maintaining product quality and operational cost-efficiency.

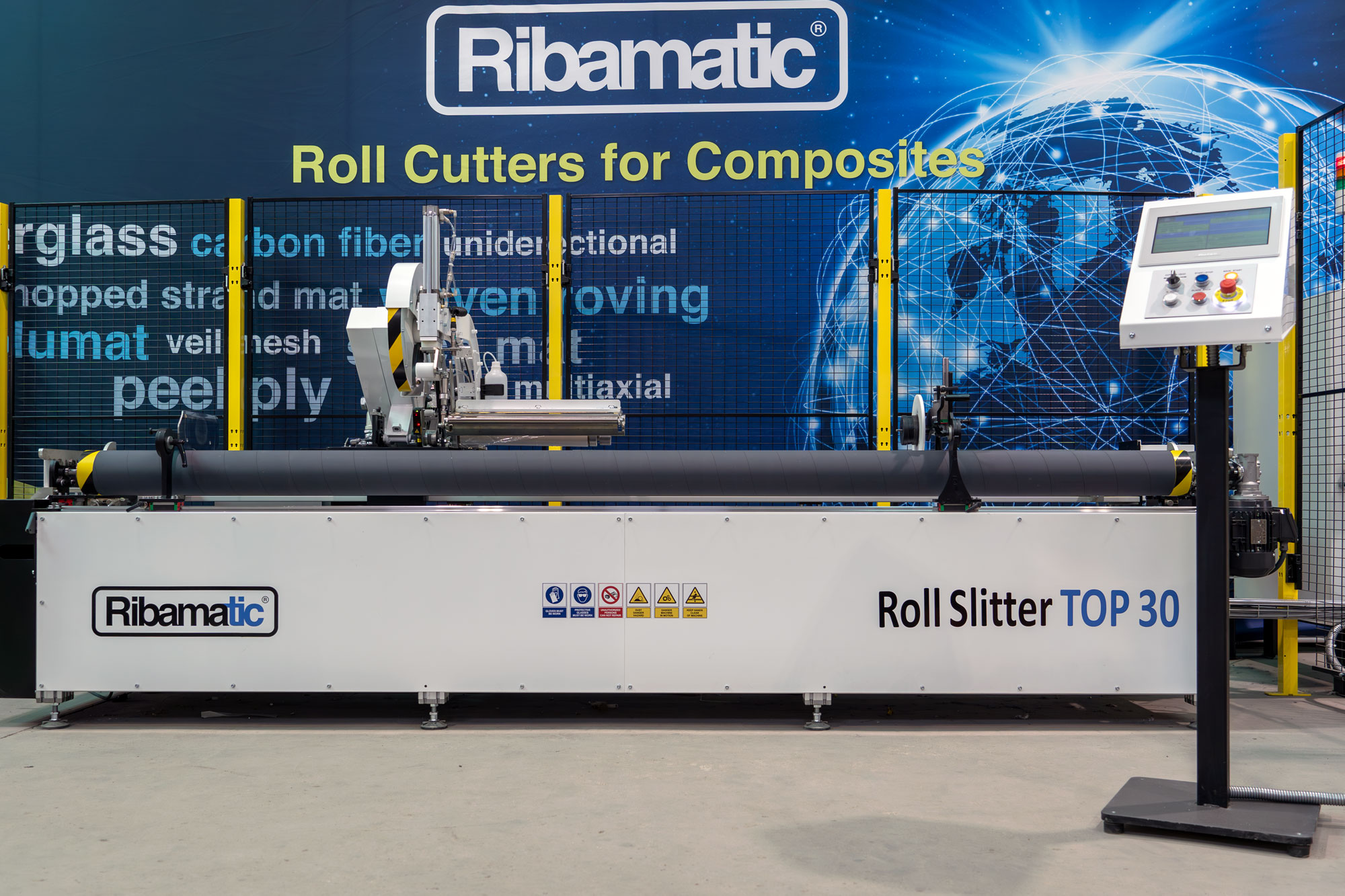

Key Components of a Roll Slitter

A roll slitter consists of several essential components that work together to ensure the material is cut correctly:

- Unwinding station: This is where the large roll of material is placed and fed into the slitter. The station ensures the material is continuously and smoothly fed into the machine.

- Slitting knives: These can be circular or straight blades that precisely cut the material into smaller rolls. Depending on the material and the desired final product, the blade configuration can be adjusted to ensure accuracy.

- Winding station: Once the material has been cut, the smaller rolls are rewound onto cores or rollers, ready for further processing or distribution.

- Control system: This manages the speed and tension of the material as it passes through the machine, ensuring consistent cuts. It also controls the positioning and operation of the slitting knives, allowing for quick and efficient adjustments.

From my personal experience with roll slitters, these components must work harmoniously to ensure precise cuts. Incorrect tension or speed adjustments can affect the final quality, emphasizing the importance of a robust control system and proper machine maintenance.

Main Applications of a Roll Slitter in Industry

Roll slitters have a wide range of applications. Some of the most common include:

- Paper industry: Used to cut large paper rolls into smaller, uniform sizes for use in printing presses, labeling machines, or the production of envelopes and notebooks.

- Plastic films and flexible packaging: In the manufacturing of flexible packaging, roll slitters are vital for dividing plastic film rolls into more manageable reels, ready to be transformed into bags, wrappers, or other packaging products.

- Adhesive tapes and labels: Precision is crucial in the production of self-adhesive labels, where strict size specifications must be met.

In my experience, roll slitters play an essential role in label production, helping to create final products that are not only visually appealing but also consistently high in quality, which is key to customer satisfaction.

How Roll Slitters Reduce Material Waste

One of the greatest benefits of roll slitters is their ability to minimize material waste. Cutting errors can lead to significant economic losses due to the amount of wasted material.

With a properly calibrated and maintained roll slitter, it is possible to ensure that every cut is accurate to the millimeter. This maximizes material utilization and reduces the need to reprocess or discard large amounts of defective products.

From my experience working with roll slitters, avoiding waste is crucial. A poorly adjusted blade or incorrect tension can lead to meters of lost material, which in turn translates into wasted time and money.

Different Types of Roll Slitters for Your Cutting Needs

There are various types of roll slitters, each designed for specific applications and materials. Among the most common are:

- Circular blade slitters: Ideal for cutting materials like paper and certain types of films. These machines allow precise adjustments for varying slit widths.

- Straight blade slitters: Used when straight, clean cuts are required, typically for thicker materials like heavy paper or thin metal sheets.

- Slitter rewinders: These machines allow for both slitting and rewinding in one continuous process, streamlining production.

Benefits of Using Modern Roll Slitters

Investing in a modern roll slitter offers several key advantages:

- Higher precision: The latest models offer automated adjustments, enabling finer, more consistent cuts.

- Reduced downtime: Advances in predictive maintenance and control systems have significantly minimized machine downtime due to failures or adjustments.

- Optimized material use: Modern slitters ensure better material utilization, reducing costs and improving sustainability.

In my experience, the latest machines equipped with automation improve efficiency considerably. The time previously spent on manual adjustments is now allocated to more productive tasks.

How to Choose the Right Roll Slitter for Your Business

When selecting a roll slitter, it is crucial to consider factors such as the type of material you will be cutting, your production volume, and the specific features you need. Key points to keep in mind include:

- Material thickness: Ensure that the machine can handle the thicknesses you commonly work with.

- Adjustability: Look for slitters that allow quick and flexible adjustments to accommodate different slit widths.

- Technical support: Choose suppliers that offer excellent after-sales support and technical assistance to minimize downtime in case of issues.

Based on my experience, I always recommend selecting a roll slitter that offers versatility in its adjustments and is backed by reliable technical support. This not only improves daily operations but also ensures any production interruptions are kept to a minimum.

Conclusion

Roll slitters are an essential piece of equipment in many industries. From material conversion to waste reduction, the use of these machines not only improves operational efficiency but also positively impacts profitability. Whether you work with paper, film, or any other flexible material, investing in a precise and modern cutting solution will make a significant difference in your production.