Industry 4.0

We have developed a software where the machine connects with the customer’s ERP through an OPC server which receives in real time all the machine data. This technology allows to the customer to get information in real time and recover the cutting information for back up control.

Fast Ethernet Internet Access Router for the High Performance Networking.

Continuing to deliver easy-to-use Internet Access solutions, our commitment to offer our customers a better solution to Internet access, and we are constantly adding unique features to our products with leading-edge technologies for today’s fast-changing network environment.

Ribamatic assemblies internet conection to all of our slitter in order to prevent and solve breakdowns on the slitter keep working and avoid stops in production.

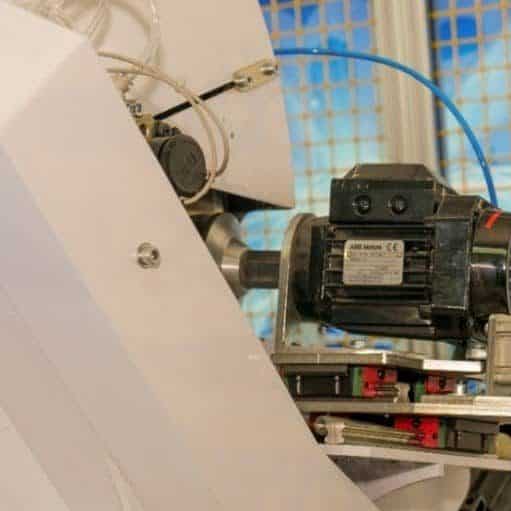

Blade sharpener

Ribamatic assembles the latest technology to sharpen both sides of the cutting blade. Our success is to keep the tool always sharp, we don’t use ceramic stones, which are harmful and dangerous and they damage the blade too fast.

The blade is quickly sharpened in a few seconds thanks to our specific grinding stones, which allow the sharpening action to be always motorized and never manual.

The sharpening action is automatic, but the frequency and time are programmed on a touch screen.

Line laser to mark the cutting position

Cut exactly where you want: The new line laser on the slitting head shows you an exact and reliable position of the cutting blade. You will find the right film edge faster than ever before. This saves time when slitting, avoids errors and is more accurate as well. The laser can be switched on or off at any time via a switch on the slitting head.

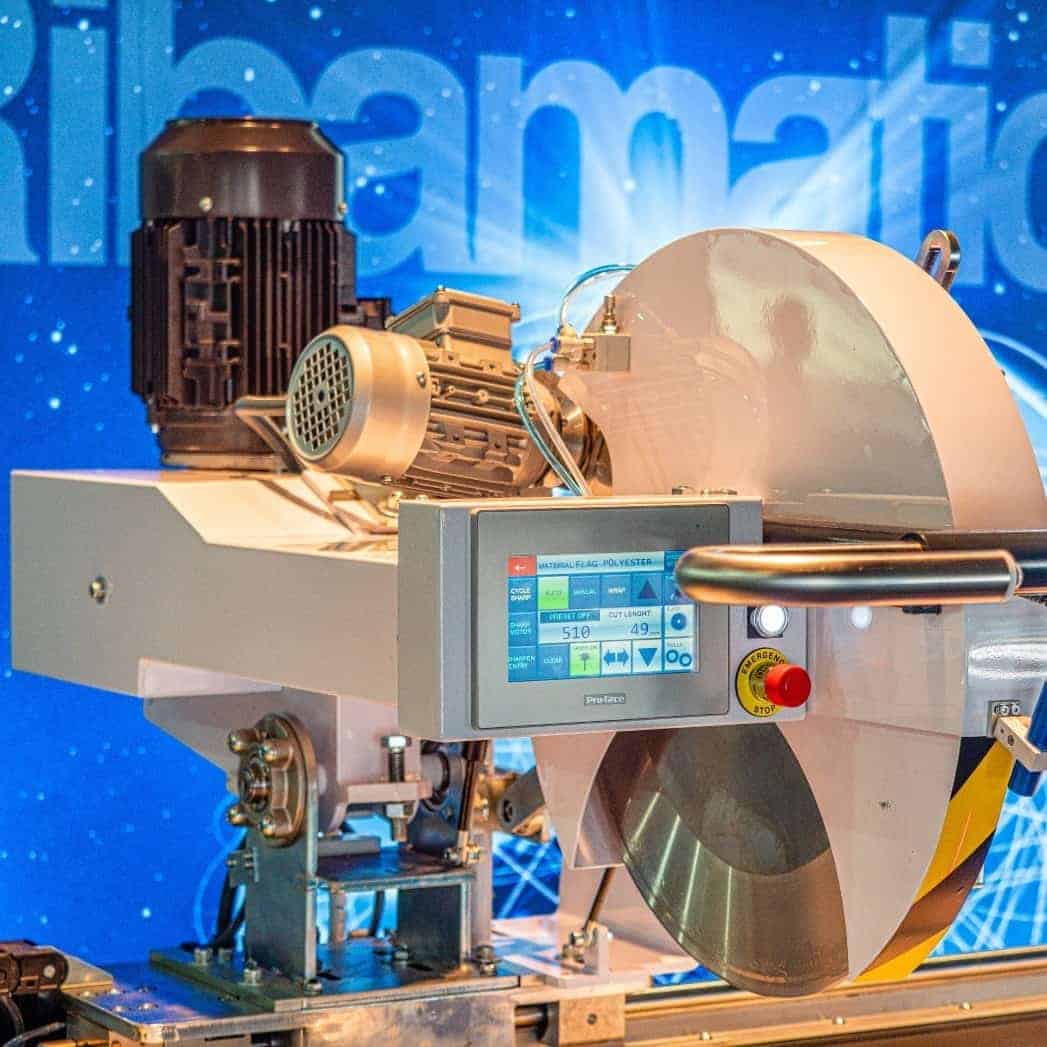

Touch screen on manual and automatic cutters

Efficient and highly productive HMI 7-inch screen, which avoids pushbutton systems.

Do not waste time adjusting parameters to cut different materials. On the screen, material programs can be created and all the settings for each one can be saved – Just choose the FABRICS or BANNER from the list and start cutting!

Sharpening frequency and time are programmable for every material.

Set the cutting width and the machine will stop automatically at the desired size.

Blade lubrication, keep away sticked glue on the blade

Cleaner and safer for the environment, it keeps the blade well lubricated at the right temperature.

The microlubrication system sprays cold air and oil mixed together to avoid fog during the cut because of the main pump, vacuum system and spray cans which are really dangerous and not healthy for the environment – Avoid fog during the cut with the microlubrication mounted on Ribamatic slitter machines.

Automatic Wrapping system for the roll

All of our machines have the option to assembly a wrapping system to cover the roll with plastic for better presentation- it allows to cut with tension and the fabric keeps clean at any time. Wrapping tension is adjustable and automatic.

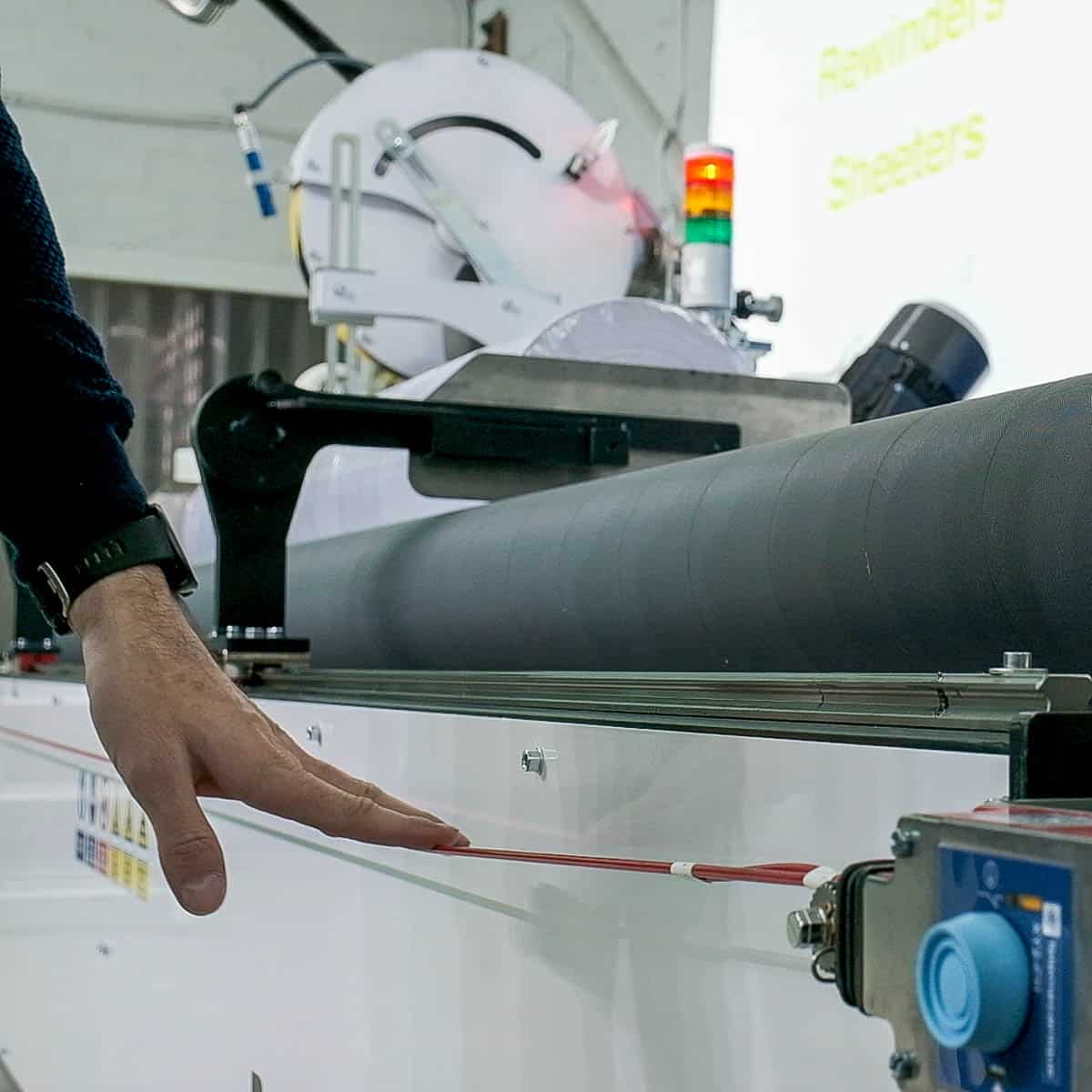

Emergency stopper

Because Safety is everybody’s job, we are committed with our customers to deliver the machines in a high safety rating. We assembly the latest technology in our manual and fully automatic machines. The fully automatic are protected with scanners and light curtains. Manual machines includes a safety Stop emergency, bimanual preventa and an emergency pull wire switch, this cable is assembled across the machine and allows to stop the cutting process from anywhere.

Borderless sides for oversized witdh rolls

We have designed our machinery and roll slitting machines just for cutting any type of rolls in diameter and length, sometimes rolls are larger than usual special for Carpet and Digital printing industries. If you buy the real 5m machine is fine but if you buy a 2m or 3m machine you are able to cut 5m as well. The roll sticks out from both sides and you will be able to slit bigger widths easily!