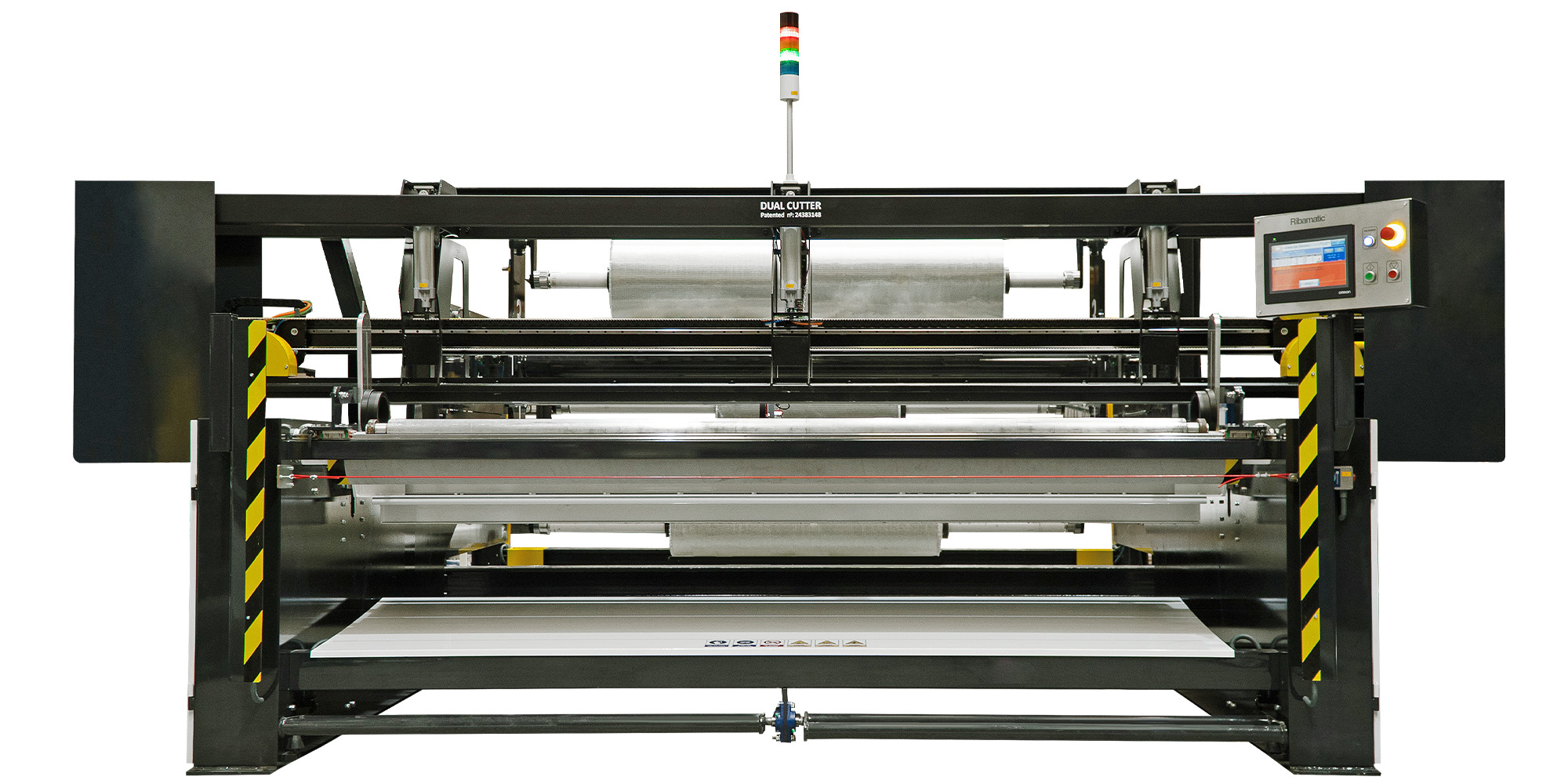

Caracteristicas Glass fiber rewinding & chamfer cutting machine

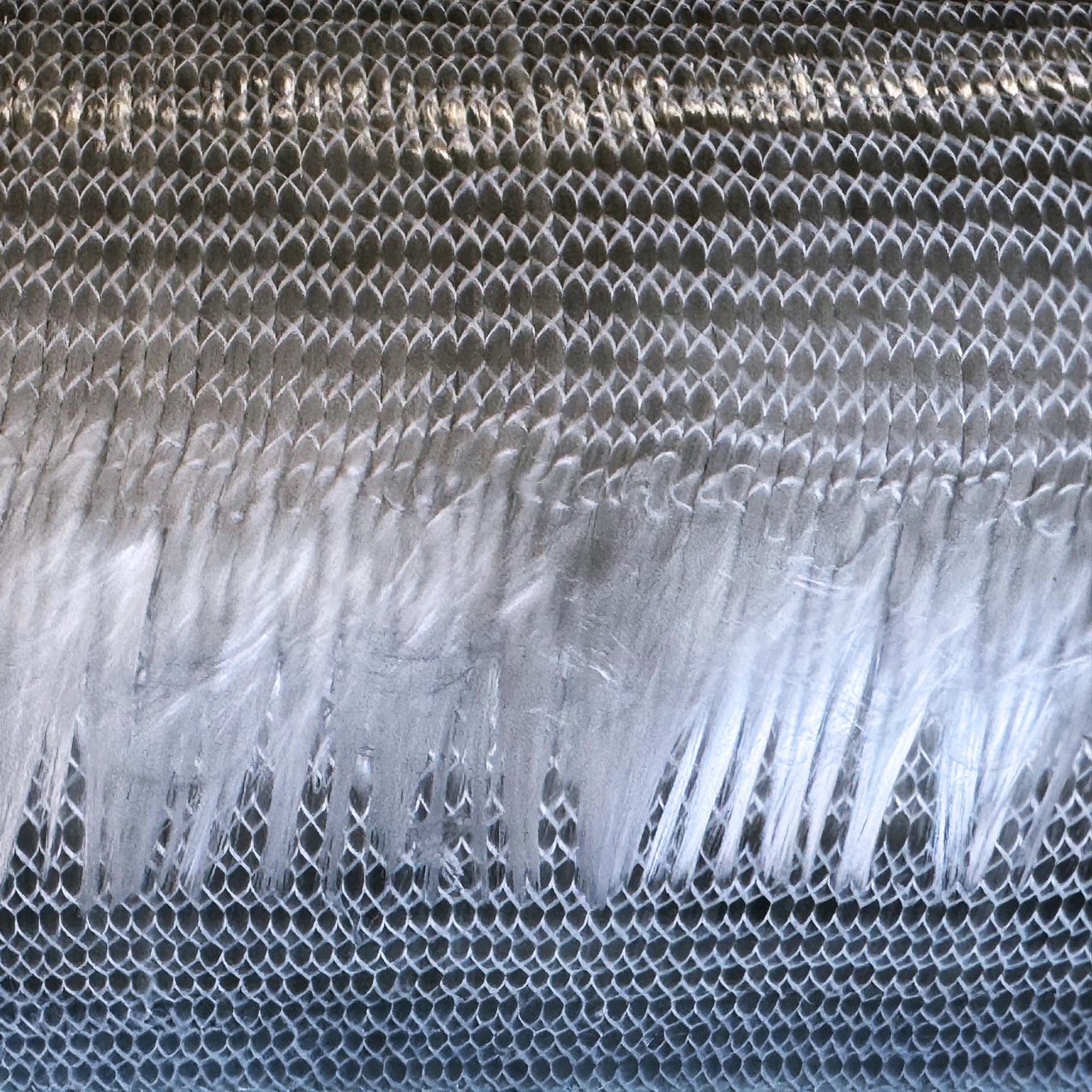

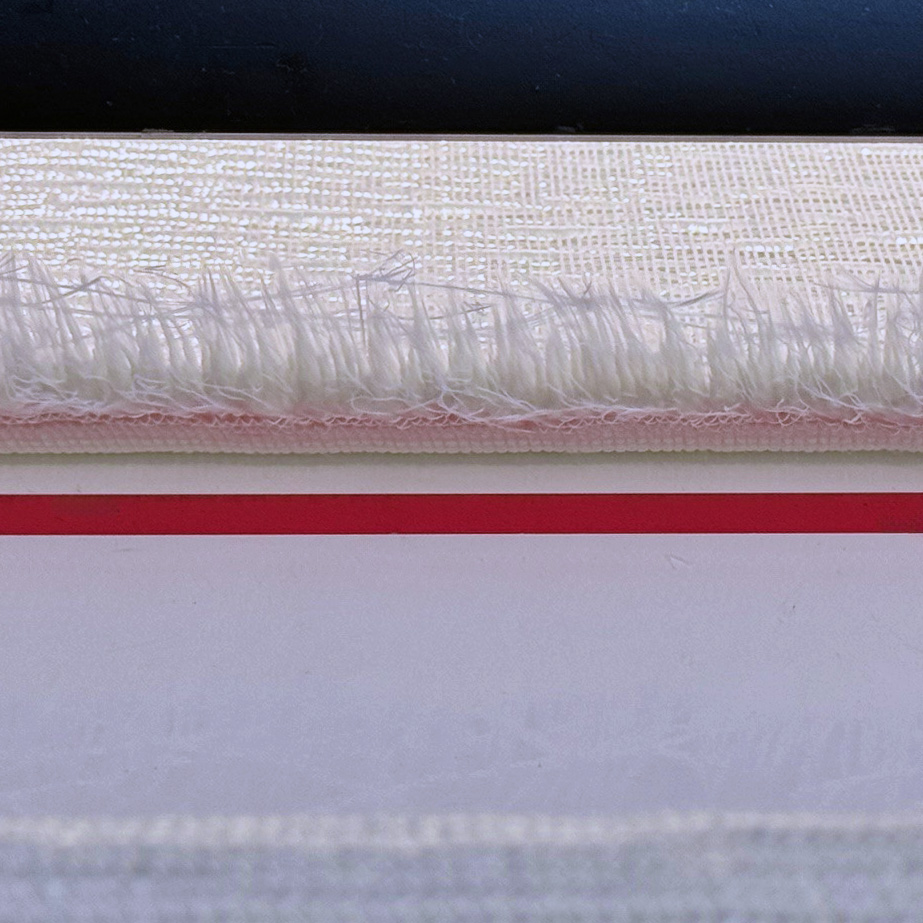

- Chamfer cutting according to quality specifications.

- High-precision straight cutting thanks to a fabric locking system that eliminates fraying.

- Anti-Wave System: eliminates transverse ripples caused by winding tension.

- Carousel loader with capacity for 4 rolls, up to 700 kg each.

- Compatible with biaxial, uniaxial, triaxial, and combo fabrics, with widths ranging from 40 to 245 cm.

- Comprehensive safety system certified CE, UL, and CSA.

Why this is best Rewinder on the market?

Multilayer rolls with different cuts and lengths.

- Easy roll change from the carousel and a truly cost-effective machine. It reduces production time when changing rolls and allows two cutting operations on a single machine.

- Programmable length with automatic stop.

- Automatic feeding from the carousel to the working and rewinding areas reduces labor requirements.

Integrated Cross and Chamfering Cutting Solution

- Easy roll change from the carousel and a truly cost-effective machine. It reduces production time when changing rolls and allows two cutting operations on a single machine.

- Programmable length with automatic stop.

- Automatic feeding from the carousel to the working and rewinding areas reduces labor requirements.

Automation and Control

- Customizable recipe management with predefined metrics and models.

- Intelligent roll and metric recognition to optimize material usage.

- Remotely updatable software for easy maintenance and improvements.

Operational Advantages

- Reduced waste and cycle time.

- Higher cutting precision and repeatability.

- Compatible with multiple fabric types and widths.

- Safety validated by external certification bodies.